Description

Blue Power Diesel Dual Fuel Conversion Kit

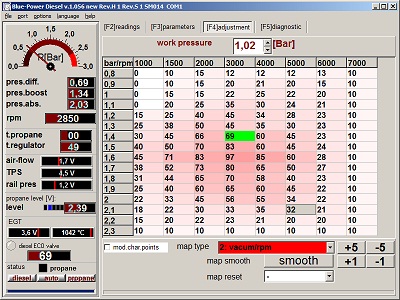

IV generation of diesel-gas sequential injection system. The most advanced sequential-injection diesel system currently available on the market. Blue-Power Diesel is perfect for diesel trucks, lorries, TIR , transporters or pickups. Works with diesel engines from 1 to 16 cylinders. With the help of Blue-Power-Diesel the engine works smoother, quieter, longer, with lower diesel consumption, and better emission, thanks to an advanced sequential injection algorithm with load-depend mixture calculator. Very easy to install. Intuitive tuning with user friendly Blue Power Diesel software.

Blue Power Kit has connection option for vehicle tracking and telemetry system, which allow to control precise diesel and LPG consumption over the GSM network as well as remote gas ECU and fleet management.

Blue Power:

- combines the best features of other controllers and allows operation simplest vehicles with a mechanical pump and the newest structures Euro 6.

- first gas-diesel controller with an in-built CAN interface.

- has enhanced precision of analogue emulators.

- cooperate with GPS module and there is a remote update via GPRS.

- provide fitters with comfort: a longer 5-meter group divided into 2 sectors combined by a hermetic joint has been used.

- developed set of analogue and digital emulators has been used. Also, a frequency emulator for flowmeters has been added.

Limitation of uneconomical drive effects

The system has two independent protections against uneconomical style of machine operation. The first degree is system adjustment which prevents a user from using a full uneconomical gas-diesel power. A second degree is control system and working parameters registration system. It informs the driver and the company about the driving style impact on consumption.

Key features:

- Sequential injection system for diesel.

- Easy to use software.

- Simple installation.

- Automatic Diesel -> CNG/LPG switchover.

- Automatic CNG/LPG -> Diesel switchover if empty tank.

- Self diagnostic ECU. Up to 32 errors saved in memory.

- Sensors predefined feature.

- Up to 6 pressure sensors defined.

- Up to 7 Vacuum/Boost sensors defined.

- Up to 8 temperature sensors defined.

- EGT sensor option. EGT sensor included in the set (premium version).

- Able to read signals from TPS, Air-Flow meter, RPM signal, EGT sensor.

- 12V compatible, 24V compatible.

- European TIR compatible.

- CDi/DCi/HDi/TDi emulator on the ECU !!!! Lower consumption of diesel.

- Safety features to eliminate the possibility of engine failure.

- Full LPG/CNG level gauge + setup. You can define any level sensor you want (resistance, Hall, V, etc.).

- Simple mixture map - for beginners/average users.

- 3 advanced maps - for advanced users.

- Long cables for the trucks, TIR.

- Diesel work time.

- LPG/CNG work time.

- Advanced rpm set up 2 inputs, one input variable 0-14 VDC.

- And many others...

Kit contain:

- ECU

- wiring harness

- map sensor

- Diesel/LPG switch

- gas temperature sensor

- EGT (exhaust gas temperature sensor)

- fuse

A patented gas injection technology

System is based on a comprehensive analysis of diesel operation cycle. It is a bad practice to transfer a direct petrol engine sequential control into diesel. A sequential control which is perfect for petrol engines can cause a diesel engine damage and does not bring any benefits. It is a common knowledge that fuel injection in diesel engines occurs at the moment of compression rather than at during suction, as it is the case with petrol engines. A gas sequential injection to diesel engine requires a considerably shorter injection and precise synchronization. Such a solution increases a failure rate when compared our patented idea. Let’s consider one of the most frequent failures – injector mechanical failure. In the case of the petrol engine, one of cylinders will be over-fuelled, a signal lamp will light up, service will replace the injector. As for diesel, if gas is supplied on a regular basis, change of blend composition in a single cylinder will cause a permanent cylinder damage and lead to expensive replacement of engine.

Blend composition

Dual fuel system is based on the combination of 2 fuels. We economize because we replace part of diesel oil with gas. Application of the innovative auto-adaptation system assures increased gas content in the blend when compared to the traditional control. As a manufacturer, we suggest using proportions up to 30% of LPG and 50% of CNG, which guarantee a proper system operation, as well as best engine performance conditions. Some of our customers use a significantly overstated gas proportions including costs for faster engine wear. As a manufacturer, we do not recommend such a practice and we do not provide guarantees in such cases.

Increase in engine parameters

Application of dual fuel system in the car causes engine power increase and a noticeable torque rise. The most important result of increased parameters is more convenient unit hauling with maximum tractor load.

Increased range

When compared to monofuel system, its dual counterpart has additional tasks which increase the range. Petrol-powered cars which drive on gas consume mostly gas. As a result, we have an impression that the range goes up. In the dual fuel system, the volume of regularly consumed fuel increases which means the real range rises.

Gearbox and extra power

A resistance of gearboxes to extra power has been confirmed in a number of cars at huge distances. First cars with our installations were tested after they had covered over 300 thousand kilometers. The wear was similar to the cars devoid of dual fuel system.

Ecological influence of fuel blending

Due to enhanced consumption parameters, CO2, solid particles and nitric oxide emission can be reduced. The studies carried out by ITS and the Faculty of Combustion Engines of the Institute of Combustion Engines and Transport at the Poznań University of Technology confirm it.